Homemade Old-Fashioned Lard Soap From Home Rendered Lard

This website may earn commissions from purchases made through links in this post.

For many years, I thought that soap making was too hard and too frightening.

Then I figured it was too expensive. Coconut oil is expensive enough to eat, let alone making soap from it.

It turns out that making soap is neither hard, frightening nor expensive.

For hundreds of years, soap has been made out of animal fats in many parts of the world, often from household drippings. It’s only recently we’ve become a bit funny about using animal fats for anything.

I know this isn’t a popular stance, but I can’t see the point of using expensive food oils in soap, like coconut oil, which puts a lot of extra strain on the environment, when animal fats are more often than not thrown away after we eat only the choice cuts of meat.

Vegans and vegetarians excepted, I can’t understand why we despise soap made from animal fat, when it’s less expensive, eliminates waste and makes excellent (some people argue superior) soap. If we’re going to eat the beast, we should be using all of it.

Lard makes a very mild, conditioning soap that is great for your skin. Unlike commercial soaps, where the glycerin is removed and sold as a separate by-product, homemade soap retains the glycerine, which is very moisturising.

Lard doesn’t lather very well, though, so if you’re expecting a bubbly lather from your soap, it’s a good idea to add another oil, like a little bit of castor oil (about 5%). Lard on its own makes a great laundry soap for homemade laundry detergent, although we use ours for personal washing and it cleans just fine. It’s a very luxurious soap.

(Note: one commenter – see below – says that her plain lard soap lathers really well, so it’s good to experiment!)

You can buy rendered lard from the supermarket, but it’s cheaper to render it yourself, especially if you’re using the trimmings from your slow-cooked pork shoulder.

When you first read through the instructions, it might sound a bit complicated. But it is easy, and only takes around 20 minutes.

A large batch will mean you only have to make soap once or twice a year to keep the whole family squeaky clean.

Because I used leftover, home rendered lard, the total cost of the soap (which was just slightly under 1 kg) was less than $1 for the lye. This is pretty frugal for around an hour’s work (including cutting the fat, the hands-on work of rendering the lard and making the soap) every six months or so.

This article will walk you through step-by-step how to make lard soap. Printable instructions are at the end of the article for your convenience.

Making Old-Fashioned Lard Soap

Soap Making Precautions

Let’s get the scary but important stuff out of the way first.

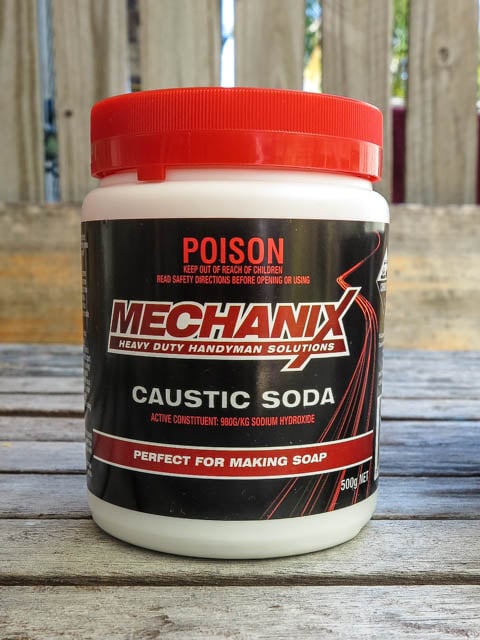

Soap is made from lye (otherwise known as caustic soda or soda ash) which is extremely alkaline. When mixed with water, it causes a chemical reaction that gives off fumes and will burn your skin on contact.

So due care must be taken when mixing the lye and water and making the soap.

Always add the lye to the water not the water to the lye, or you might get a volcanic eruption happening.

Wearing gloves and protective glasses is advisable. If you do happen to accidentally get some on your skin, keep some vinegar close at hand to help neutralise the burn.

When the lye and water mix, there is a chemical reaction, and they give off fumes, so it’s best to mix them in a well-ventilated area or outside.

And make soap when the kids and the pets are not around.

Lard Soap Ingredients

There are three basic ingredients for making soap:

- oils or fats

- water (distilled, filtered or rainwater is best)

- caustic soda/lye

You can also add essential or fragrance (synthetic) oils, colours and botanicals for speciality soaps.

Lye is a naturally occurring substance, and while it’s the scary part of soap making, there’s no way of making soap without it.

You can actually make lye yourself, by leaching water through ash from a fire, but it’s also readily available and cheap to buy from the supermarket or hardware store. I got mine from Woolies and used very little to make around 1 kilo of soap, so it’s going to last for years!

You can find caustic soda in the cleaning section of the supermarket along with the ‘Draino’. Make sure you get the pure caustic soda and not drain cleaner, which can have other ingredients added.

Once mixed with the oils or fats in your soap and left to dry, the soap ‘saponifies’ and becomes less alkaline. At a pH of around 8 – 11 and no longer burns the skin (although our skin is actually slightly acidic at around 4.5 – 5.5 pH, so any soap is going to be drying if you have sensitive skin, eczema or dermatitis).

Glycerine is made when the lye reacts with the fats and remains in the soap. Glycerine is very moisturising for the skin.

For soap making supplies, kits and equipment, check out Green Living Australia.

Lard Soap Making Equipment

It is often recommended to have separate equipment for soap making, but I just use the kitchen equipment I have on hand, and wash it well, using plain vinegar first to neutralise the lye, then hot soapy water.

You will need:

- Accurate kitchen scales

- A large pot (not aluminium)

- A Pyrex jug or smaller pot

- A wooden spoon (I do have a separate wooden spoon for soap making)

- Kitchen thermometer

- A stick blender (optional, but will save you a lot of stirring)

- A spatula

- A mould (I used a plastic tub – clean recycled plastic containers is another option or silicone cake moulds)

- Rubber gloves and glasses (I wore sunglasses and made the soap outside. The glasses are to protect your eyes from splashes. I don’t want to scare you off because making soap is quite easy – but it’s always better to be safe than sorry.)

The Soap Making Process

Soap can be made by using either the cold or hot process. Today, I’m sharing how to make cold processed soap, which is quicker and easier.

There’s very little difference between the two processes except that the soap is cooked after you combine the fat and lye in the hot process, whereas in the cold process, the fat is heated initially, but then there is no further cooking.

Weighing and calculating your soap recipe

All ingredients, including your water, must be weighed accurately. I have an old-fashioned set of scales with a dial, but if you’ve got digital scales, all the better.

Place your pot on the scales and tare your scales (set them to zero). Then add your lard and weigh it.

Now enter the amount of lard you have into an online soap calculator (like this one or this one or this one) to work out how much water and lye you will need.

Whenever you read a soap recipe, you should always run it through a soap calculator or two to double check.

Once you have a soap recipe you like, you can write it down and use it again and again. If you’re not sure how much lard you’ll have after rendering, start by weighing what you’ve got each time and calculating the recipe from there.

[A note on superfatting (you will see this in the soap calculators): Superfatting is a term that means adding more fat or oils to your soap than the lye can react to. Superfatting makes your soap more moisturising. It also acts as insurance that there’s enough oil to react with the lye so there’s no lye leftover, which can burn if there is.

I superfatted my soap at 5%, just to be on the safe side. Superfatted soap isn’t great soap for the laundry, so if you’re making laundry soap, you want to superfat as little as possible. If you don’t superfat your soap, just be careful when unmoulding it (wear your glasses and gloves) and look for any spots of lye that have not reacted with the oils.]

Now place a jug on the scales and tare them again, and weigh your water according to the recipe the soap calculator works out for you.

Then in a separate container, weigh out the lye.

Making your lard soap

Prepare your mould(s) by greasing them with a little lard. I place a piece of baking paper in my mould like you would do with a cake, but I’m not sure it’s necessary. If you use an empty milk carton or similar, you can simply cut the mould away (make sure it is spotlessly clean, though).

Melt the lard in a pot on the stove, and then let it cool until it reaches between 37°C-51°C.

While the lard is melting, outside, or in a well-ventilated area, add the weighed lye slowly to the water in a Pyrex jug, stirring as you add (I don’t have a jug, so I’m using a pot. A jug would be easier).

Let the lye mixture cool until it too reaches between 37°C-51°C.

Pour the lye mixture into the melted lard, stirring and making sure you don’t splash it as you pour. Give it a stir for a minute or two to combine and then use your stick mixer to mix until the soap comes to ‘trace’, which means it looks kind of like a thin custard. Lines from the mixer should stay visible for a few seconds after you swirl it around. It can take about 5 minutes until the soap reaches trace or around 15 minutes if you stir with a wooden spoon.

If you want to add fragrance, now’s the time to do it. Give it a quick whizz to mix in the essential oils.

Pour the soap into your prepared mould. You can use a spatula to scrape all of the soap out of your pot and smooth the top of the mould.

Wrap your mould in an old towel and put it somewhere safe for two or three days for the soap to set.

Once your soap has gone hard, you can turn it out of the mould with care and cut it into bars.

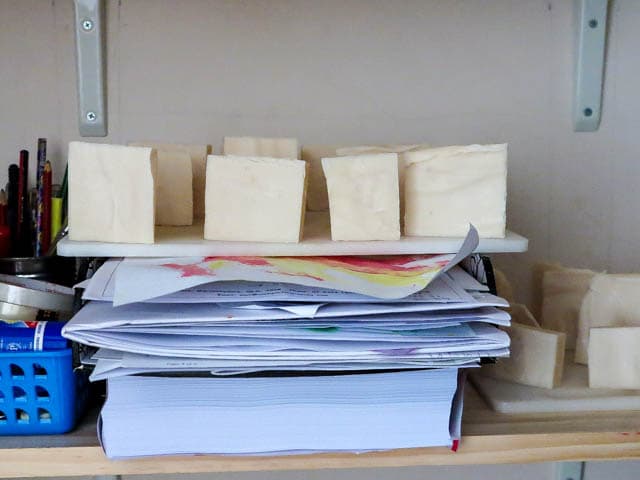

Place the bars on an old chopping board or mat and leave in a cool dark place for a few weeks to cure and go hard. This will allow the saponification process to finish and will make your bars last longer. Turn your bars every few days, or whenever you remember, to enable them to dry evenly.

I cure ours in our Harry-Potter-esque cupboard under the stairs. Please excuse the filing.

It was hot and humid when I made soap, so they took weeks and weeks to go hard. However, they were fine to use after about a week, just a bit soft.

You can pretty your bars up by shaving the edges with a clean vegetable peeler, or you can mill them into speciality soaps, which I’ll cover in another post.

Homemade Lard Soap

Make soap from home rendered lard.

Materials

- Rendered lard (see measurements below)

- Water (distilled, filtered or rainwater is best)

- Pure caustic soda/lye (with no other ingredients)

Tools

- Accurate kitchen scales

- A large pot (not aluminium)

- A Pyrex jug or smaller pot

- A wooden spoon just for soap making

- Kitchen thermometer

- A stick blender (optional, but will save you a lot of stirring)

- A spatula

- A mould (see notes above)

- Rubber gloves and safety glasses

- White vinegar (for spills)

Instructions

- Prepare your soap mould(s) by greasing them with a little lard. You can also line them with baking paper if desired.

- Using an accurate set of scales, place your pot on the scales and reset them to zero. Add the lard and weigh it.

- Using an online calculator (i.e. calculator one, calculator two, calculator three) enter how much your lard weighs to calculate how much water and caustic soda/lye you will need.

- Write down your soap recipe according to the calculator.

- Remove the pot from the scales and place your jug on them. Reset the scales to zero. Weigh your water according to the soap recipe from the soap calculator.

- Remove jug. Place a third container on the scales and reset them to zero. Weigh your caustic soda according to the recipe from the soap calculator.

- Melt the lard in a pot on the stove until it reaches between 37°C and 51°C.

- In a well ventilated area, add the weighed caustic soda/lye to the water, stirring as you add it.

- Let the lye mixture cool until it too reaches between 37°C and 51°C.

- Once both the lye mixture and the lard are at the same temperature, pour the lye mixture into the melted lard. Stir as you pour making sure not to splash.

- Stir to combine and then use your stick mixer to mix the soap until it comes to trace.

- Once soap has come to trace, pour into your prepared mould.

- Wrap mould in a towel and place somewhere safe for two or three days for the soap to set.

- Once your soap has gone hard, turn it out of the mould and cut into bars.

- Leave to cure in a cool dark place for a few weeks to cure and go hard. Turn bars every few days to dry evenly.

Notes

Always add the lye to the water to avoid unsafe chemical reaction.

Wear gloves and protective glasses and long sleeves for safety.

When lye and water mix, it gives off fumes. Mix in a well-ventilated area and don't breathe the fumes in.

Make soap away from kids and pets.

If splashes on skin occur, you can neutralise them with white vinegar.

Recommended Products

As an Amazon Associate and member of other affiliate programs, I earn from qualifying purchases at no extra expense to you.

Have you made your own soap? Process: scary or easy? What’s your favourite soap recipe?

Thanks for recipe – will give it a try. Just came across your blog – when I have a chance I’ll grab that cup of tea and look through your information – looking forward to it. Janine

Just made my first batch of lard soap. I actually made it with leftover bacon grease. Been curing for two weeks now and the bars are nice and hard already. I have even washed my dirty hands with it as a test and got clean hands. In case any one is wondering I can not smell any bacon in this soap. I will definitely be making more.

Thanks Mark, that’s great!

Just found your recipe a couple of weeks ago and gave it a try. I had leftover lard from making pork crackling and it was so creamy and white I wanted to use it as there was way too much to cook with. My batch worked out beautifully. Thank you for this recipe and the calculators.

That’s great to hear! Thanks for letting me know :)

Thanks for the walk thru your work. I will try it at home.

I was cleaning out my cupboards and found some expired store-bought lard. I wouldn’t use it for cooking as it is probably rancid. Would this be a good use for it or should I just throw it out.

I wouldn’t use rancid lard.

I am a biochemist. Scholarly articles done on soap making using rancid oils show that rancid oils produce very high quality soaps that show no difference than their non rancid fat counterparts. The rancid odor is utterly destroyed in the chemical process, and all fats are saponified equally. The only difference might be that color may be different based on the color of the fat at time of saponification.

Also, environmental studies done on recycling used fats into soaps from fryer cooking, showed the same results. And a new question in recycling is the reuse of restaurant fats for the soap industry. Used fats from cooking, such as from a fryer, must be rendered first to remove food impurities.

Also a found discovered truth from reading diaries, is that rancid fat is exactly what our ancestors used to make soap. They did not use perfectly good cooking lard to make soap. They always made soap from fats that were no longer usable for cooking, or fats that had turned rancid on the shelf.

Bottom line: Fats react as fats, irrespective of their rancidity, or having been previously heated and used. So fear not you’ll be just fine

Sounds really interesting. I have some pigs in Barbados and we are planning to slaughter leading up to Christmas so I will definitely try this out. who knows may make good Christmas gifts if I pretty up and make smell nice!! Otherwise will try for laundry

Hello,

I just want to comment on what you said about lard soap doesn’t lather well. That is contrary to my experience. I am fairly new at making soap but I like to experiment. In the beginning, I followed the recipes to the T. Then I wandered off and now I made all my soap using only bacon fat and no other oil. I found it to lather much better than in my previous batches where I used different oils. Just want to share my experience.

Thank you.

Cam

Hi Cam,

That’s awesome, thanks for sharing your experience! I’m going to update the article.

I haven’t made soap in a while and your post prompted me to get back into it. I did have a go at rendering fat I bought from the butchers. It took a lot longer than 30 minutes for the render but then I had quite a lot of fat to get through. And, the smell…OMG it was bad. I don’t think I would do it again, maybe if I could do the render outside then yes I would.

Yes, it does smell a bit! Outside would be better.

Hope that it is the one like my beloved grandma who used it for clothes stains as best than commercial products. Will make this soon. Thank you!!!

Living in Roma, Italia for the next two years. But before moving from my home in Salt Lake City, Utah USA, I made three batches using lard as my primary fat.I had always mixed fats – using up to three different fats. My soap turned out beautifully. I would say however, a little on the soft side. My next batch will be made Italia with only lard. Excited for the tutorial. Thank you so much!!

So glad to hear it turned out well. Enjoy Roma! What a change :)

I have been searching for someone to post a good article on animal fat based soap!

When trying to live sustainably and off the grid there is absolutely no logic to using fats and oils from half way around the world. We have two dairy farms as our neighbours and my father-in-law has a beef farm. There’s flax and rapeseed grown within spitting distance. Desperately googling replacing olive oil and coconut oil in soap only to see people saying “it is what it is!” Isn’t good enough. Especially as my grandmother and her mother certainly didn’t have olive oil and coconut oil to make their soaps…!

Glad you found the article useful! You can totally make soap from any type of fat. There would surely be rapeseed oil soap recipes??? I love that you’re thinking local!

I have been using only lard and sometimes mixing a little tallow (oil from rendered beef fat). We have a few cows and pigs. I love the soap. I use mostly lard. Out of the total oil I use about 1/4 tallow to 3/4 lard. I also make a powder from oatmeal and add that to some of my batches. It is good for skin issues.

I have been making soap for 10 years and about 6 months ago started working with a blend of lard and other oils. I can’t wait to see how a lard only bar turns out.

Jennifer

waterlilysoap.com

Hope it turns out well :)

So my question is )I may have missed it in the instructions although w read the twice ☺️) do you heat the water before adding the lue?

No. Cold water. The lye and water make a chemical reaction and will get hot once you combine them.

We raise Berkshire pigs, so i have access to a lot of leaf fat which I can render. When you use the soap for laundry, do you grate it first? And how much do you use? Thank you.

Yes, I grate it first for laundry powder. Here’s how I make it: https://www.frugalandthriving.com.au/homemade-laundry-detergent/.

Oh my goodness! Save the leaf lard for cooking and use the lesser stuff for soaping.

so i have a question. I made homemade lye out of hardwood ashes and have liquid lye. Would I still use the same measuring statistics in the calculator or is it already good to go because it is liquified already? Thanks in advance and have a nice day.

No idea. That’s hardcore! Mother Earth magazine might help you though.

I am a costumed interpreter at a historic home and am trying to learn to make soap the really old fashioned way with potash made from ashes, rainwater, and lard. I can’t use scales to measure because the pioneers in 1800 making soap on their farms would not have had scales. That being said, I made lye water using the bucket method and concentrated it down over a fire. I did the egg and potato tests, and both floated like they were supposed to. For my lye to lard ratio, I used 3/4 cup lye to 2 cups lard plus 1 tablespoon salt to help the soap harden. I heated the lye and lard to 120*F and poured the lye into the lard. It came to trace after about an hour of stirring with a wooden spoon, and I poured it into the mold. Right now, after 4 days of sitting, it’s still about as soft as the filling of a pumpkin pie, but it is beginning to pull away from the sides of the mold.

Any thoughts on the method, ratio, etc? I want to be able to demonstrate this to visitors on our “farm days.” I won’t be selling the soap.

Thanks!

Sharron

Wow! How cool! But I have no idea how to answer your question. That’s beyond my experience, sorry. But it would be awesome to hear how you go.

Mel

The Foxfire Museum offers regular classes on making lard based soap, outside over a fire. The local woman who teaches the class walks through each step as authentic to the old Appalacian ways as possible. If you’re in the north GA area it would be a terrific way to learn.

Thanks for the resource. That would be cool to learn.

I love all the information in addition to your recipe, I have been so curious about lard soap and why it isn’t as common and the benefits of utilizing the natural elements around us, you explained it all so well! Thank you! I love your recipe and have been able to make several batches with great results. It is my favorite thing to make and give. Thank you, thank you! I wanted to ask what natural herbs have you added and what is your favorite?

Your article said that there’s a PDF version of the lard soap recipe. Didn’t find it.

Never mind. I found the printable version. Thanks!

I have been making soap for several years and have begun to use lard quite often. The lard only bars are great and I find they lather very well. I absolutely love your instructions. I am so happy to hear other people are using lard in their soap. I render mine down quite often instead of throwing it away. I use my soap for gifts for friends and family.

I am trying to use more local products. It seems crazy to be ordering oil from halfway around the world.

I love your website! Thanks so much for all the great information!

Hi loved your info on soap making. Just wondering how do you clean your leftover tallow from cooking? Ive made Tallow a few times and some have turned out great, some hard, some soft and I have know idea why lol but I have never worked out how to store/clean fat from a roast?

Started this process on Sunday! So far it’s hardened up nicely, cut it into bars to cute today. Thank you so much for sharing this tutorial! I’ve wanted to make soap “the old fashioned way” since I was a kid reading Little House books:p So excited!

Hi Jessica, glad to hear your soap turned out well.

I have never made soap before, but have been gathering ingredients – including lard from a heritage breed pig we split with some friends! So, if I have a bunch of Rosemary and want to make Rosemary Mint, can I cook up my own scent instead of using essential oils? I was thinking I would simmer fresh or dried Rosemary in water for a good bit of time, and evaporate it to concentrate it and use this for the water portion of the soap-making process… will this work? Do you have any ideas on quantities? I also have some nice lemon verbena…

Hi Anna, I’m not sure, to be honest. If you Google tea in soap there are some tips. Here’s a couple of posts I found that talks about using infused herbs. https://www.aussiesoapsupplies.com.au/how-to-infuse-herbs.html or https://lovelygreens.com/guide-herbs-flowers-soap-recipes/

If you end up trying it, I would love to hear how it went.

Hi Anna,

You can definitely use tea is the water portion of your soap but the scent will generally not last through saponification. Hope this helps!

Fantastic! Great to find a fellow Aussie to follow, makes finding products so much easier! Thank you for this post, tallow is an underrated and unappreciated natural wonder! It makes the most divine salve as well!

Hi Michelle, nice to meet you. Tallow salve sounds interesting!

Was great to read this Mel. I am going to try making soap with mutton fat, having just butchered a sheep today, instead of feeding it to the working dogs (who with the drought in western Queensland are more house dogs than working).

I’d love to hear how you go.

This is a great recipe! My husband made soap with the fat from a moose last year and I found it very moisturizing. He used a similar method, similar process, but lost the recipe/instructions. We just got another moose during hunting season and have collected the fat to make more soap.

I want to help this year, but I want to make it smell pretty. Last year’s batch had a very strong moose smell. How do I do this?

Moose soap! Cool. There are instructions for purifying tallow on the bumblebee apothacary blog. I would check those out and see if they are helpful. Mel

I’ve been making soap for a while now. I’ve been using tallow instead of lard though. I got a good deal on 50 pounds of it. It makes a nice soap, too